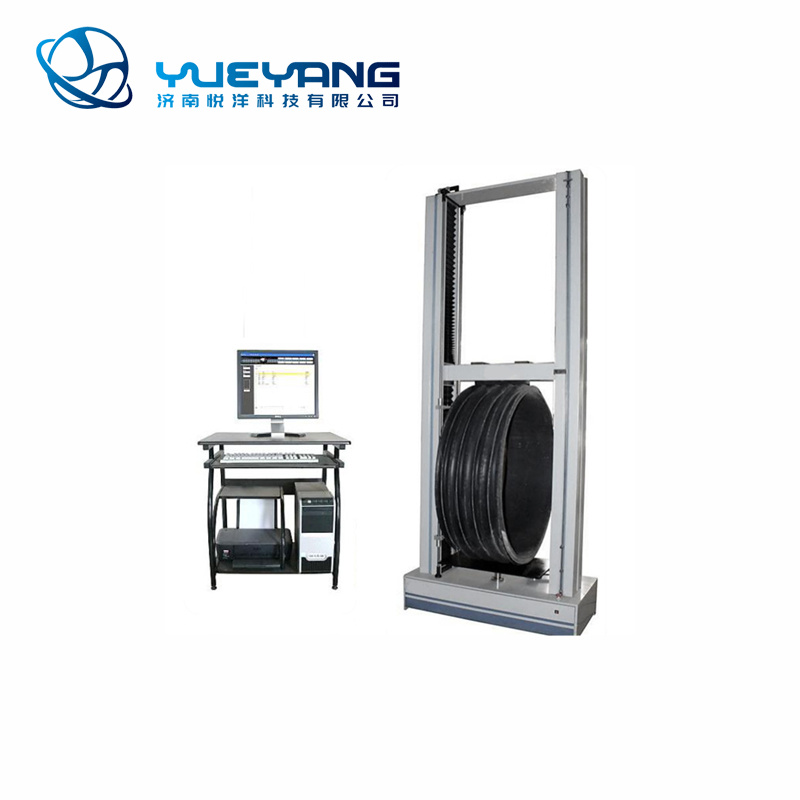

Injin Gwaji na YYP-WDT-W-60E1 na'urar gwaji ta lantarki (taurin zobe)

Injin gwajin taurin zobe mai sarrafa ƙananan na'urori na WDT jerin sukurori ne mai amfani da gubar biyu, mai masaukin baki, sarrafawa, aunawa, da tsarin haɗakar aiki. Ya dace da gwada halayen injina na bututun filastik daban-daban, bututun haɗaka da bututun FRP, kamar taurin zobe, sassaucin zobe, gwajin daidaita lanƙwasa da rabe-raben rabewa, da kuma gwajin taurin haɗin gwiwa, shimfiɗa waya ta ƙarfe, shimfiɗa tsiri na ƙarfe da sauransu. Don biyan buƙatun bellows, bututun lanƙwasa da ƙa'idodin gwajin bututun filastik daban-daban. Tsarin software yana ɗaukar hanyar haɗin Windows (nau'ikan harshe da yawa na iya biyan buƙatun ƙasashe da yankuna daban-daban), kuma yana da ayyukan saita da adana sigogin gwaji, tattara bayanan gwaji, sarrafawa da nazarin bayanan gwaji, nuna lanƙwasa bugawa da buga rahoton gwaji, da sauransu. Ana amfani da wannan jerin na'urorin gwaji sosai a cibiyoyin bincike na kimiyya, kwalejoji da jami'o'i, sassan duba inganci, da kamfanonin samar da bututu.

1. Sashen watsawa na wannan jerin na'urorin gwaji ya ɗauki tsarin AC servo na alama da aka shigo da shi, tsarin rage gudu, sukurori na ƙwallon daidai da kuma tsarin firam mai ƙarfi.

2. Tsarin auna ƙarfin firikwensin guda biyu yana guje wa hana karkacewar babban bututun mai girman gaske yadda ya kamata, yana rage yuwuwar lalacewar firikwensin kuma yana tabbatar da daidaiton gwajin.

3. Yi aiki tare da tsarin auna diamita na ciki na musamman don gwajin taurin zobe, aunawa kai tsaye da daidaito, da kuma auna daidaito na canje-canjen diamita na ciki na bututu.

4. Bisa ga buƙatar ƙara babban na'urar aunawa don tsawaita tensile a gwajin hutu, za a iya auna nakasar daidai tsakanin layin da ke da tasiri a samfurin.

5. Wannan injin ya fi daidai fiye da samfuran da ake samu a kasuwa, akwai nau'ikan aunawa cikin sauri, ban da halayen injina na gwajin bututu, ana iya amfani da shi don tensile, matsi, lanƙwasawa, modulus na roba, barewa, tsagewa da sauran kaddarorin injina na gwajin kayan, tare da aiki mai tsada.

6. Jerin injunan gwaji zuwa fasahar zamani mai ci gaba a cikin kyakkyawan yanayi, babban daidaito, kewayon sauri mai faɗi, ƙarancin hayaniya, sauƙin aiki, daidaito har zuwa matakin 0.5, da kuma samar da nau'ikan takamaiman bayanai/kayan amfani ga masu amfani daban-daban don zaɓa.

7. Tare da ayyuka da yawa na kariya kamar ɗaukar kaya fiye da kima, don haka aikin gwajin ya kasance lafiya da aminci. Wannan jerin samfuran sun wuce takardar shaidar CE ta Turai.

Dangane da ƙa'idojin gwajin bututu na GB/T 9647, GB/T 18042, ISO 9969 da sauran ƙa'idodi, ya kuma cika buƙatun GB/T 1040, GB/T 1041, GB/T 8804, GB/T 9341, ISO 7500-1, GB 16491, GB/T 17200, ISO 5893, ASTM D638, ASTM D695, ASTM D790 da sauran ƙa'idodi.

| Samfuri | YYP-WDT-W-60E1 |

| Nisan Gwaji | 1200/3500≤60KN |

| diamita | Ф3500 |

| Nisa tsakanin ginshiƙi da ginshiƙi | 1200mm |

| Gudun Gwaji | 0.01mm/min-500mm/min(mai yiwuwa ne koyaushe) |

| Daidaiton Gudu | 0.1-500mm/min <1%;0.01-0.05mm/min <2% |

| Shawarar Magance Matsuguni | 0.001mm |

| Nisan Auna Matsi | 0.4%FS-100%FS |

| Yanayin sarrafawa | Sarrafa PC;Fitar da firinta mai launi |

| Tushen wutan lantarki | 220V 750W 10A |

| Girma (mm) | 1280×620×3150 |

| Nauyi | 550Kg |

| Daidaitacce | Na'urar auna diamita na ciki ta bututu |

| Zaɓuɓɓuka | Babban na'urar auna nakasa |

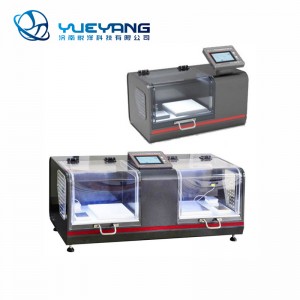

Kamfaninmu ne ya ƙirƙiro tsarin manhajar gwaji (tare da haƙƙin mallakar fasaha mai zaman kansa), sigar harsuna da yawa don biyan buƙatun masu amfani a ƙasashe da yankuna daban-daban.✱ Cika ƙa'idodin hanyoyin gwaji na ISO, JIS, ASTM, DIN, GB da sauran ƙa'idodi

✱ Tare da canja wurin aiki, tsawaitawa, kaya, damuwa, damuwa da sauran hanyoyin sarrafawa

✱ Ajiyar yanayin gwaji, sakamakon gwaji da sauran bayanai ta atomatik

✱ Daidaita kaya da tsawo ta atomatik

✱ü An ɗan daidaita hasken don sauƙin daidaitawa

✱ linzamin kwamfuta mai sarrafa nesa da sauran sarrafa ayyuka daban-daban, mai sauƙin amfani

✱ Yana da aikin sarrafa tsari, yana iya zama mai sauƙi kuma mai sauri don gwadawa akai-akai

✱ Hasken yana komawa ta atomatik zuwa matsayin farko

✱ Nuna lanƙwasa mai ƙarfi a ainihin lokaci

✱Zai iya zaɓar matsin lamba, tsawaita ƙarfi, lokacin ƙarfi, da kuma lanƙwasa gwajin ƙarfin lokaci

✱ Canjin daidaitawa ta atomatik

✱ Matsayi da kwatanta lanƙwasa na gwaji na rukuni ɗaya

✱ Binciken faɗaɗawa na gida na lanƙwasa gwaji

✱ Yi nazarin bayanan gwaji ta atomatik