Kayayyaki

-

(China) YYP113-4 PAT Fixture

Gabatarwar Samfuri:

Ana amfani da PAT Fixture ne musamman don gwada ƙarfin haɗin kwali mai rufi.

-

(China) YYP113-3 Babban Yanke Samfurin FCT

Gabatarwa:

Mai yanke samfurin FCT samfurin samfuri ne na musamman da ake buƙata don gwajin ƙarfin matsin lamba mai lebur

(FCT) na allon da aka yi da roba 8, wanda zai iya yanke samfurin da sauri da daidai

Yankin da aka ƙayyade. Na'ura ce mai dacewa don allon corrugated da kwali

masana'antun, binciken kimiyya da kuma sa ido kan inganci da kuma sassan dubawa.

-

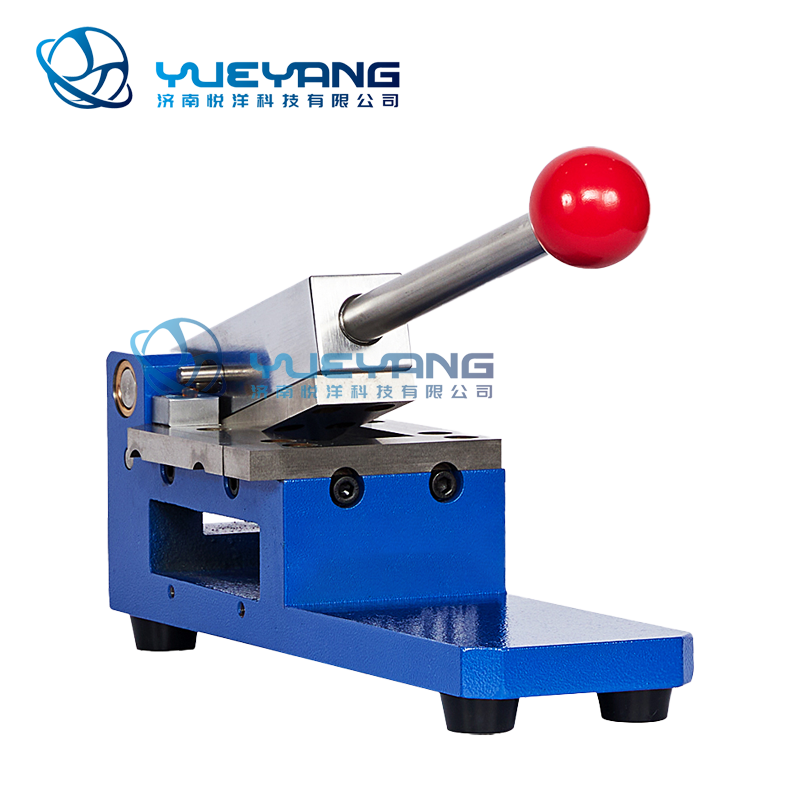

(China) YYP113-2 ECT Samfurin Yankan Samfuri

I.SamfuriNigabatarwa:

Ana amfani da samfurin matsi na gefen (mannewa) galibi don gefen

Gwajin matsin lamba da gwajin mannewa, yanke shi cikin sauri da daidai

Girman da aka ƙayyade na samfurin, shine kwali da kwali mai laushi

samarwa, binciken kimiyya da kuma kula da inganci da dubawa

sassan kayan aikin gwaji na musamman.

-

(China) YYP113-1 RCT Samfurin Yankewa

Gabatarwar Samfuri:

Samfurin matsi na zobe ya dace da yanke samfurin da ake buƙata don ƙarfin matsi na zoben takarda.

Yana da samfurin musamman da ake buƙata don gwajin ƙarfin matsin lamba na takarda (RCT), kuma ingantaccen taimakon gwaji ne

don yin takarda, marufi, binciken kimiyya, duba inganci da sauran masana'antu da

sassan.

-

(Sin) YYP113 Mai Gwaji Mai Murkushewa

Aikin samfur:

1. Ƙayyade ƙarfin matse zobe (RCT) na takardar tushe mai laushi

2. Auna Ƙarfin matse gefen kwali mai laushi (ECT)

3. Tantance ƙarfin matsewa mai lebur na allon corrugated (FCT)

4. Tantance ƙarfin haɗin kwali mai rufi (PAT)

5. Ƙayyade ƙarfin matsewa mai faɗi (CMT) na takardar tushe mai laushi

6. Ƙayyade ƙarfin matsewa na gefen (CCT) na takardar tushe mai laushi

-

(China) YYP10000-1 Mai Gwaji da Ƙarfafa Samfurin Yankewa

Injin yanke samfurin crease&stiffness ya dace da yanke samfurin da ake buƙata don gwajin crease&stiffness kamar takarda, kwali da takarda mai siriri.

-

(China) YYP 10000 na'urar gwajin crease&stiffness

Daidaitacce

GB/T 23144,

GB/T 22364,

ISO 5628,

ISO 2493

-

(Sin) YYCS820P Spectrophotometer mai tsayin benci

Gabatarwa

Wannan na'urar auna haske ce mai sauƙi, mai sauƙin sarrafawa kuma mai cikakken daidaito. Tana ɗaukar allon taɓawa na inci 7, cikakken kewayon tsayin tsayi, tsarin aiki na Android. Haske: haske D/8° da watsawa D/0° (an haɗa da UV / an cire UV), babban daidaito don auna launi, babban ƙwaƙwalwar ajiya, software na PC, saboda fa'idodin da ke sama, ana amfani da shi a dakin gwaje-gwaje don nazarin launi da sadarwa.

Amfanin Kayan Aiki

1). Yana ɗaukar yanayin haske D/8° da kuma yanayin watsawa D/0° don auna kayan da ba su da haske da kuma waɗanda ba su da haske.

2). Fasahar Nazarin Bakan Hanya Biyu ta Hannuwan gani

Wannan fasaha za ta iya samun damar yin amfani da bayanai na aunawa da na'urar a lokaci guda don tabbatar da daidaiton kayan aiki da kwanciyar hankali na dogon lokaci.

-

(China) YY501B Mai Gwajin Yawan Yaɗa Ruwa

I.Amfani da kayan aiki:

Ana amfani da shi don auna yadda tufafin kariya na likitanci ke iya shiga, da kuma nau'ikan yadudduka daban-daban, da kuma kayan da aka yi da kayan haɗin kai, da kuma fina-finan haɗin kai da sauran kayayyaki.

II. Ma'aunin Taro:

1.GB 19082-2009 – Bukatun fasaha na tufafin kariya na likita 5.4.2 danshi mai shiga jiki;

2.GB/T 12704-1991 —Hanyar tantance yadda danshi ke shiga yadudduka – Hanyar kofi mai shiga danshi 6.1 Hanya Hanya ta sha danshi;

3.GB/T 12704.1-2009 – Yadi mai yadi – Hanyoyin gwaji don shigar da danshi – Kashi na 1: hanyar sha danshi;

4.GB/T 12704.2-2009 – Yadi mai yadi – Hanyoyin gwaji don shigar da danshi – Kashi na 2: hanyar fitar da danshi;

5.ISO2528-2017—Kayan takarda - Ƙayyade yawan watsa tururin ruwa (WVTR) – Hanyar Gravimetric (tasa)

6.ASTM E96; JIS L1099-2012 da sauran ƙa'idodi.

-

(China) YY-90 Gishiri Mai Gwaji - Allon taɓawa

IUsai:

Injin gwajin gishiri ana amfani da shi ne musamman don maganin saman abubuwa daban-daban, gami da fenti. Electroplating. Inorganic da kuma coated, anodized. Bayan man hana tsatsa da sauran maganin hana tsatsa, ana gwada juriyar tsatsa na samfuransa.

II.Siffofi:

1. Tsarin da'irar dijital mai sarrafa nuni na dijital da aka shigo da shi, ingantaccen sarrafa zafin jiki, tsawon rai na sabis, cikakkun ayyukan gwaji;

2. Lokacin aiki, allon nuni yana da nuni mai motsi, kuma akwai ƙararrawa mai ƙararrawa don tunatar da yanayin aiki; Kayan aikin yana amfani da fasahar ergonomic, mai sauƙin aiki, mai sauƙin amfani;

3. Tare da tsarin ƙara ruwa ta atomatik/da hannu, lokacin da matakin ruwa bai isa ba, zai iya sake cika aikin matakin ruwa ta atomatik, kuma gwajin ba ya katsewa;

4. Mai sarrafa zafin jiki ta amfani da allon taɓawa na LCD, kuskuren sarrafa PID ± 01.C;

5. Kariyar zafi sau biyu, gargadin matakin ruwa mara isa don tabbatar da amfani mai lafiya.

6. Dakin gwaje-gwajen ya yi amfani da hanyar dumama tururi kai tsaye, saurin dumama yana da sauri kuma iri ɗaya ne, kuma lokacin jiran aiki ya ragu.

7. Mai watsawa mai siffar mazugi na hasumiyar feshi tare da ƙarar hazo da hazo mai daidaitawa yana warwatsa bututun gilashin daidai gwargwado, kuma a zahiri yana faɗowa akan katin gwaji, kuma yana tabbatar da cewa babu toshewar gishirin crystallization.

-

(China) YYP643 Gidan Gwajin Fesa Gishiri

YYP643 ɗakin gwajin feshi na gishiri tare da sabon sarrafa PID yana da faɗi sosai

an yi amfani da shi a cikin

Gwajin feshi na gishiri na sassan da aka yi wa electroplated, fenti, shafi, mota

da sassan babura, sassan jiragen sama da na soja, yadudduka na kariya na ƙarfe

kayan aiki,

da kayayyakin masana'antu kamar tsarin lantarki da na lantarki.

-

(China) YYP-400BT Mai Rage Guduwar Narkewa

Mai ƙididdige kwararar narkewa (MFI) yana nufin inganci ko ƙarar narkewar narkewar narkewar ta hanyar ma'aunin ma'aunin kowane minti 10 a wani takamaiman zafin jiki da kaya, wanda ƙimar MFR (MI) ko MVR ta bayyana, wanda zai iya bambance halayen kwararar da ke cikin thermoplastics a cikin yanayin narkewar. Ya dace da injiniyan robobi kamar polycarbonate, nailan, fluoroplastic da polyarylsulfone tare da zafin narkewa mai yawa, da kuma don robobi masu ƙarancin zafin narkewa kamar polyethylene, polystyrene, polyacrylic, resin ABS da resin polyformaldehyde. Ana amfani da shi sosai a cikin kayan filastik, samar da filastik, samfuran filastik, petrochemical da sauran masana'antu da kwalejoji da jami'o'i masu alaƙa, sassan binciken kimiyya, sassan duba kayayyaki.

-

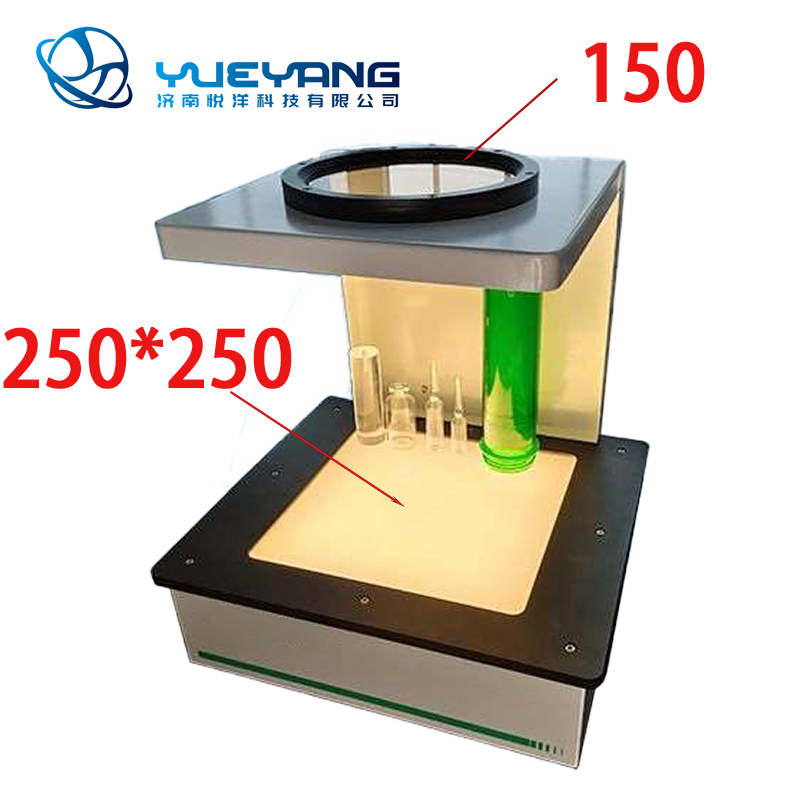

(China) YYPL03 Mai Duba Tsarin Polariscope

YYPL03 kayan aiki ne na gwaji da aka ƙera bisa ga ƙa'idar "GB/T 4545-2007 Hanyar gwaji don damuwa ta ciki a cikin kwalaben gilashi", wanda ake amfani da shi don gwada aikin ƙara yawan kwalaben gilashi da samfuran gilashi da kuma nazarin damuwar ciki na

kayayyakin.

-

(Sin) YYP 114E Stripe Sampler

Wannan injin ya dace da yanke samfuran tsiri madaidaiciya na fim ɗin da aka shimfiɗa a gefe biyu, fim ɗin da aka shimfiɗa a gefe ɗaya da fim ɗin da aka haɗa, daidai da

Bukatun da ake buƙata na yau da kullun na GB/T1040.3-2006 da ISO527-3:1995. Babban fasalin

shine cewa aikin yana da sauƙi kuma mai sauƙi, gefen spline ɗin da aka yanke yana da kyau,

kuma ana iya kiyaye ainihin halayen injina na fim ɗin.

-

-

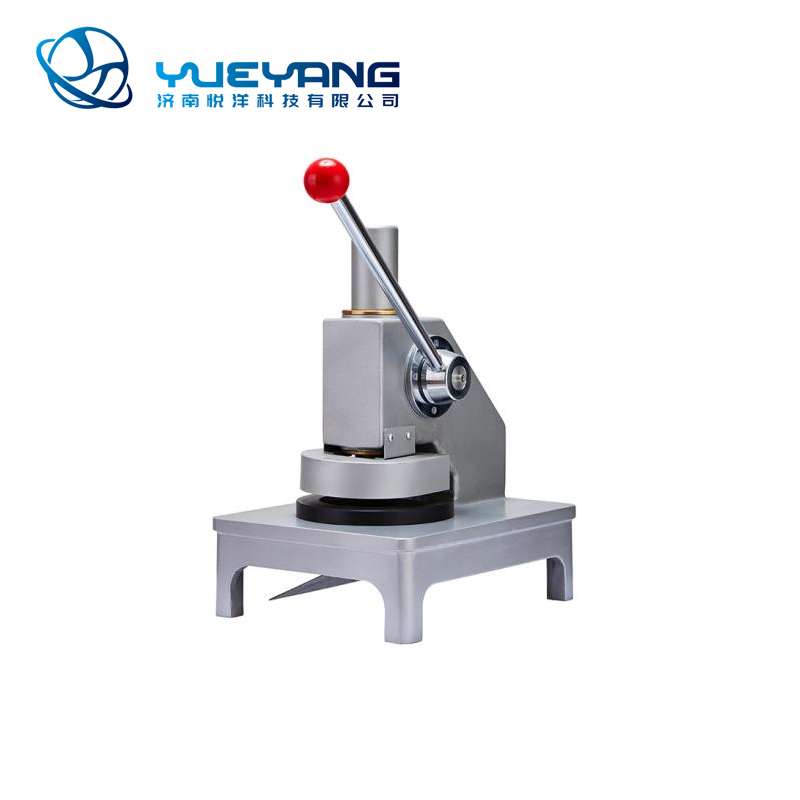

(China) YT-DL100 Mai Yanke Samfurin Da'ira

Mai samfurin Circle wani samfuri ne na musamman don tantance adadi

samfuran takarda da takarda na yau da kullun, waɗanda za su iya sauri da kuma

daidai yanke samfuran yanki na yau da kullun, kuma shine gwaji mafi dacewa na taimako

kayan aiki don yin takarda, marufi da kuma kula da inganci

da kuma masana'antu da sassan dubawa.

-

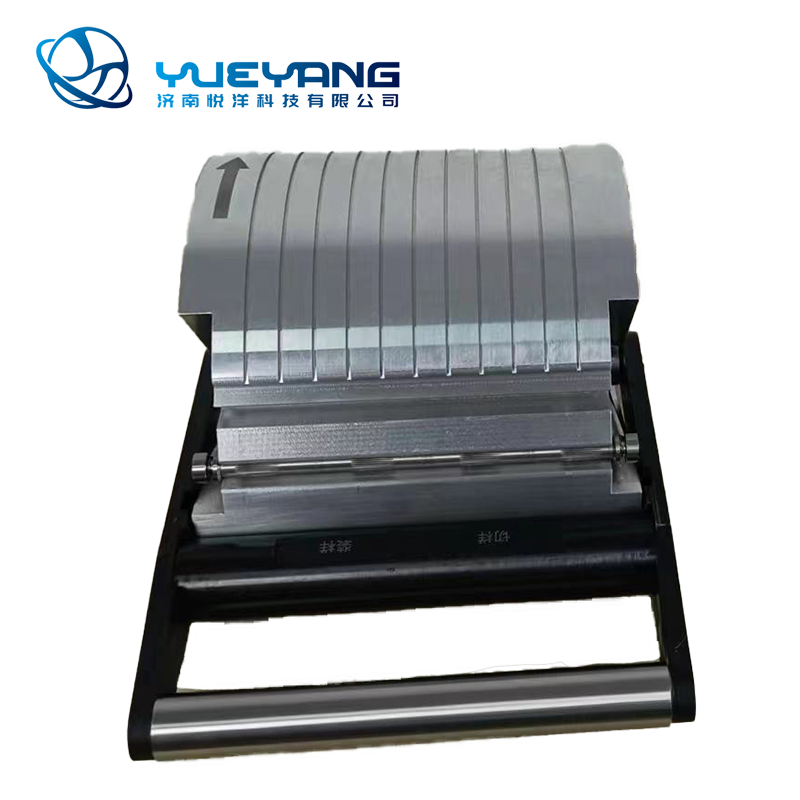

(Sin) YY-CMF Concora Matsakaici Fluter

Concora medium fulter kayan aikin gwaji ne na asali don yin corrugating lebur

danna (CMT) da kuma mashin gefen corrugated (CCT) bayan an yi masa corrugated a ciki

dakin gwaje-gwaje. Yana buƙatar amfani da shi tare da na'urar latsa zobe ta musamman.

na'urar gwaji ta samfurin da matsi

-

(China) YYP-L12A Babban Injin Dubawa Mai Daidaito

YYP-L12A mai ƙarfi da ƙwarewa wajen yin pulping paper mannewa shine dakin gwaje-gwajen yin pulping paper mannewa a cikin babban ruwa mai kauri ko kuma rabuwar ruwa mai kauri. Shin dakin gwaje-gwaje yana amfani da shi don sarrafa allon pulping, lalata takardar, da kuma shigarwar babban gwajin takardar clean, yana kimanta tsarin ruwa mai kauri na sake farfadowa, ƙarin sinadarai da kayan aiki mai inganci, yana nazarin ɗayan shigarwar mataimakan sunadarai na takarda. Wannan halayyar injin, daidaitawar saurin hannu, saurin juyawa na dijital shine ƙarfin juyi mai girma.

-

(China) YYP-L4A Lab Valley Beater

Ana amfani da wannan injin sosai a matsayin na'urar gwaji ta yau da kullun ga JIS da TAPPI. Ba kamar na'urar bugun da aka saba ba, ana gyara na'urar, kuma ana ɗora mata kaya akai-akai a kan farantin kai, ta haka ne ake ba da matsin lamba iri ɗaya. Yana da kyau musamman a bugun da ba shi da matsala da kuma bugun da aka yi da ruwa. Don haka yana da tasiri sosai don sarrafa inganci.

-

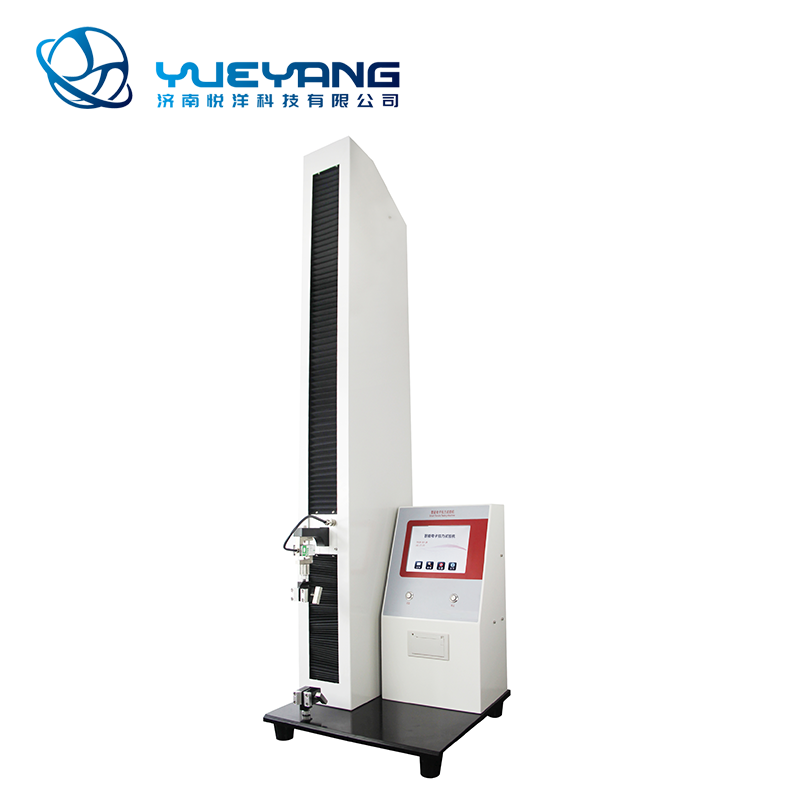

(China) YYP101 Injin Gwajin Tashin Hankali na Duniya

Halayen fasaha:

1. Tafiyar gwaji mai tsawon milimita 1000

2. Tsarin Gwajin Motar Panasonic Brand Servo

3. Tsarin auna ƙarfin alamar CELTRON ta Amurka.

4. Gwajin numfashi